Guide to Basic Sewing Stitches Every Bag Manufacturer and Designer Should Know

Sewing is the thread that holds the fashion industry together, quite literally! Every manufactured garment, accessory, or soft good is a product of its fabric and the stitches, threads, and finishes that hold it together. Understanding different stitch types is not just a matter of craftsmanship for bag manufacturers and designers. It’s essential for ensuring durability, performance, and brand quality.

This guide retains the foundational knowledge of basic sewing stitches but reframes them through the lens of bag construction, prototype development, and design aesthetics, offering insights valuable to anyone working in the soft goods industry.

Why Stitch Selection Matters in Bag Design

Unlike garments, bags experience concentrated stress at handles, seams, zippers, and structural reinforcements. The wrong stitch can mean premature wear, structural failure, or a product that doesn’t meet consumer expectations. Stitching also impacts the look and feel of your final product, whether you’re creating a rugged tactical backpack or a refined leather handbag.

By mastering both hand and machine stitches, designers can prototype more effectively, while manufacturers can choose the best method for longevity and brand appeal.

A Guide to Basic Sewing Stitches (With Bag Construction in Mind)

Hand Stitches

Before sewing machines became everyday commodities in the home and factory, garments were made solely by hand. This included every step of the sewing process, hemming an edge, joining two separate pieces of cloth, finishing a seam, etc. Many garments today are still sewn by hand utilizing the following basic stitches. These are especially useful in early-stage prototyping or finishing fine detail areas on custom or luxury bags.

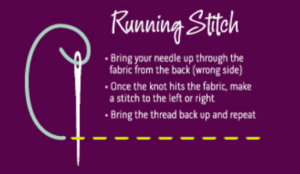

Running Stitch

The running stitch is the most basic and commonly used, in which the needle and thread simply pass over and under two pieces of fabric. It’s the same as a basting stitch, except it is sewn more tightly to create a secure and permanent bind. The technique can be identified by the spaces left between each stitch on both sides of the fabric, creating a dashed thread line. Use it to quickly test form factors or mock up samples.

Basting Stitch

A basting stitch is one of the simplest stitches in sewing, used to temporarily hold together two pieces of fabric. Think of it as a “rough draft” later replaced by a more secure and permanent stitch. Sometimes also called a tack stitch, it is done quickly with a simple over/under motion, resulting in a long, loose stitch easily removed. In bag design, it’s useful when layering heavy fabrics or aligning straps before final assembly.

Back Stitch

The back stitch is a variation of the running stitch, but with each needle pass, the needle and thread double back on itself. This eliminates the visible spacing, the dashed effect, seen in the running stitch and instead creates a more polished straight line of thread on the fabric’s surface. Great for small-scale production or high-strength seams in custom bag designs.

Catch Stitch

A catch stitch, or cross-stitch, is a standard sewing technique for hemming. The use of this stitch creates a zig-zag series of X’s on the underside of a piece of fabric. Strong and flexible, these stitches are barely visible on the outside of a garment and offer a clean finish for raw edges. Use it in linings or to secure pocket interiors.

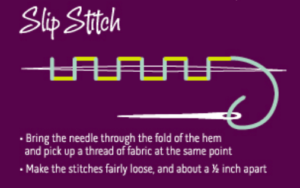

Slip Stitch

The slip stitch is a strong, sturdy, and permanent way to finish a garment. This is another great stitch for securing hemlines. However, unlike the catch stitch, using a slip stitch results in a nearly invisible bond on both sides of the fabric. Ideal for sewing brand labels or decorative patches without showing visible seams.

Machine Stitches

The advent of the sewing machine in the early 18th century completely revolutionized the apparel industry, streamlining production. It changed how the traditional clothing manufacturing process operated. Today, machines construct most apparel and bags. These machines often possess a wide range of capabilities, and almost every machine contains the ability to perform these three basic stitches.

Straight Stitch

The straight stitch is a series of straight stitches equidistant from one another, all in uniform length and spacing. It is the most common stitch that serves as the backbone for nearly all sewing machine varieties. In bags, this is your go-to for seams, edge stitching, and structural reinforcement, especially on canvas, leather, or ballistic nylon.

Backward Stitch

The backward stitch is merely the machine’s ability to carry out the straight stitch in reverse. This capability helps secure the beginning and end of any other stitch. Additionally, this keeps the thread from unraveling or losing its shape. Use it at the start and end of all major seamlines or attachment points like handles and straps.

Zigzag Stitch

The zigzag stitch is a sewing technique where the needle and thread move back and forth at alternating angles. It is the second most common stitch after the running stitch and is present in nearly all sewing machines today. Its strength is often used to finish seams and raw edges, reinforce buttonholes, and in stretchable fabrics. For bags, it can reinforce flexible areas or be used decoratively on outer shells and pocket flaps.

Most sewing machines, both industrial and home models, possess the ability to make buttonholes and create a variety of hemming and decorative stitches. It all depends on the specific machine, with each brand and model offering its unique assortment.

In the soft goods world, bar tacking and double-needle topstitching are additional machine capabilities that are crucial for reinforcement in high-stress areas like strap bases and closures.

Stitching Applications by Bag Type

- Tote Bags: Topstitching around edges for polish; slip stitches for inner label applications.

- Utility Backpacks: Straight and backward stitches at all stress points; bar tacks on straps.

- Luxury Handbags: Slip and catch stitches for clean interiors; decorative topstitching for branding.

- Travel Gear: Zigzag and straight stitches on zippers, handles, and expandable pockets.

Call Softline Today

Softline Brand Partners, a soft goods manufacturing industry leader, offers integrated design and manufacturing solutions. Whether you’re crafting a tech-forward travel backpack or an artisan leather clutch, our team ensures each detail, from stitching to branding, is crafted with precision and quality.

Contact Softline Brand Partners for expert assistance in developing patches, labels, and fully integrated stitching plans that resonate with your brand’s message and appeal.