As one of the oldest textile materials, leather has been used for generations to create beautiful, high-quality goods. This article will guide you through the key leather grades—top grain, full grain, and genuine leather—to help you make informed design choices.

Leather Basics

Leather is made by processing animal hides, like cattle, sheep, or goats. The treatment process is called “tanning”. The tanning process uses tannins in chemicals, natural compounds, and even vegetables to turn raw animal hides into the durable and pliable material we know as leather. The tanning process plays a key role in determining the end quality of a leather product.

The two most common methods of tanning are chrome tanning and vegetable tanning. Chrome tanning uses chromium sulfate to preserve raw hides, producing soft yet strong leather. Alternatively, vegetable tanning uses vegetable proteins from organic materials like bark to transform the raw hide into leather. This is one of the oldest leather tanning techniques.

Common Leather Terminology

Before diving into the different leather grades, it may be helpful to have some basic definitions of leather terminology:

- Grain: refers to the surface texture of leather. Leather grain is the natural patterns and marks on an animal hide, which can greatly vary between grades.

- Finish: an applied surface treatment that affects the leather’s appearance and feel. Finishes can be matte, glossy, or somewhere in between, and they may influence the leather’s durability and resistance to wear and tear.

- Patina: a unique leather quality that gives the leather a distinct character and luster as it is worn and exposed to the elements.

Full Grain Leather

Full-grain leather is the highest leather grade, prized for its natural look. This leather retains the outermost layer of the animal hide, including the grain and any imperfections. This results in a unique look highlighting the hide’s history and character. Full-grain leather is associated with an authentic and rugged appearance, marked by natural creases and scars from the animal’s life.

Full-grain leather is typically tanned using vegetable tanning. This tanning process is time-consuming and artisanal, contributing to the high cost and quality of full-grain leather. This kind of leather’s quality and distinctive appearance make it a preferred choice for various products, including high-end footwear, luxury bags, and furniture.

Benefits and Drawbacks

Using full-grain leather has many advantages. First, it is renowned for its unmatched quality, leading to long-lasting leather products that retain their beauty. Additionally, its natural imperfections and patina development create a one-of-a-kind look that will last a lifetime. Though full-grain leather is beautiful and durable, it has several drawbacks. First, as it is the highest quality leather grade, it is more expensive than other types of leather. The labor-intensive tanning process and the hides’ quality contribute to this high price tag. Additionally, this kind of leather is more susceptible to scratches and marks because it retains the hide’s natural surface.

In summary, full-grain leather is prized for its authenticity and durability. Its unique texture and look appeal to a wide variety of products. While it has a high price tag, full-grain leather is a long-lasting and timeless investment.

Top Grain Leather

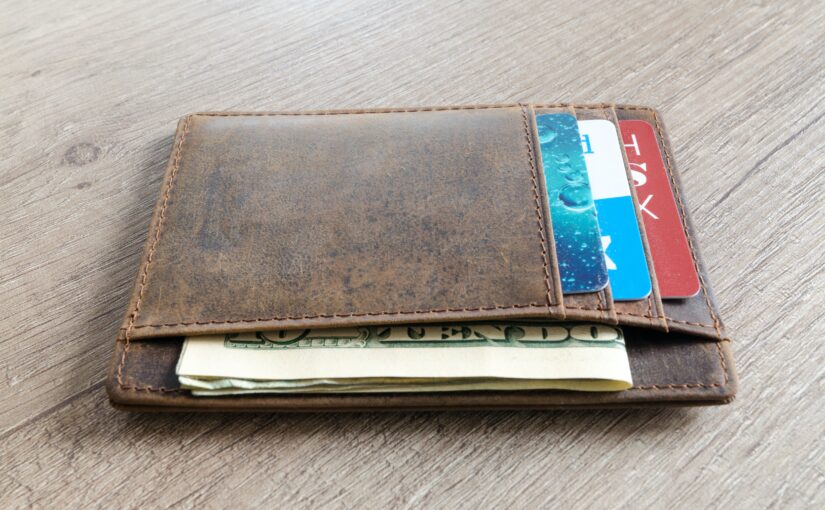

Top grain leather is a high-quality leather grade known for its polished and refined appearance. Unlike full-grain leather, top-grain leather undergoes a sanding process that removes the outermost layer of the hide. This eliminates surface imperfections, resulting in a uniform texture and a sleek finish. This sanding process also removes the appearance of inconsistent grain patterns, leaving behind a steady grain pattern. This leather grade is not only elegant and beautiful, it is also highly durable. Top-grain leather’s refined appearance and durability suit various applications, including luxury fashion and accessories.

Benefits and Drawbacks

The appearance of top-grain leather grade is often noted as one of its finest qualities. With minimal imperfections, it appeals to those looking for a sleek and sophisticated look. Additionally, unlike full-grain leather, top-grain leather can withstand day-to-day wear and tear without the risk of indentations and creases.

Similarly to full-grain leather, the quality of top-grain leather comes at a great cost. It is one of the more expensive leather grades available, which limits its appeal to the general public. Additionally, while it is smoother than full-grain leather, it may retain some imperfections from the natural hide and the sanding process.

In summary, top-grain leather is a great choice for those looking to design a leather product that is sleek and simple. However, its high price point may deter budget-conscious shoppers and designers.

Genuine Leather

The term “genuine leather” can be very misleading, suggesting a high-quality product when the term represents a wide range of leather. This leather is made from layers of animal hide left over after removing the top-grain and full-grain layers. This makes it a more affordable option for leather products.

Genuine leather can vary greatly in texture and pattern due to the nature of the leftover hide. Leather manufacturers can emboss a grain pattern into the leather to create a uniform pattern. Additionally, the tanning process contributes to the wide variety in quality of genuine leather. This kind of leather can be tanned using a variety of methods, including both chrome and vegetable tanning. Due to its affordability, genuine leather is used in many everyday products, including belts, lower-priced footwear, and mass-produced furniture.

Benefits and Drawbacks

Genuine leather has a variety of uses, making it a great choice for leather goods designers. As a more budget-friendly option, it is accessible to many consumers. Additionally, it is available in a wide variety of grain patterns and colors, so it applies to various products.

While it is an affordable option, genuine leather is less durable than high-quality leather grades. Additionally, genuine leather does not age like full-grain and top-grain leather. It does not develop a patina like its higher-grade alternatives.

Genuine leather is an affordable option within the leather family. While it does not possess the same longevity or unique qualities as higher-grade leather, it offers versatility to those with budget constraints.

Making Informed Choices Regarding Leather Grades

When designing a small leather good, choosing the right kind of leather is important. Understanding the difference between full-grain, top-grain, and genuine leather is crucial for ensuring your leather product aligns with your preferences and budget. Working with an expert in the leather industry, like Softline Brand Partners, can help ensure your leather product comes out exactly the way you envision.

Softline Brand Partners is a passionate team dedicated to creating exceptional leather products for brands of all sizes, from startups to Fortune 500 companies. With a commitment to quality and excellence, we are an industry leader in producing small leather goods, like watch straps, wallets, and patches. From concept to creation, we source top-notch materials, forge meaningful relationships with suppliers, and manufacture with care in our domestic and overseas factories. If you’re ready to elevate your brand with top-of-the-line soft goods, contact Softline Brand Partners today.