Why Do Factories Have Minimum Order Quantity (MOQ)?

Leather goods are a popular consumer and branding product. From watch straps to bags to furniture, leather is used in various products, styles, and aesthetics. For designers, leather is often chosen due to its natural beauty and durability. When taking a design to manufacturing, designers are often confronted with a leather manufacturer’s minimum order quantity, or MOQ. This concept can leave many designers needing clarification. In this article, we will discuss the intricacies of MOQ in the leather goods industry. From its definition to purpose to consumer benefits, this guide will give you a comprehensive understanding of MOQ.

What is MOQ?

Minimum Order Quantity (MOQ) is a manufacturing concept that signifies the minimum number of units a customer must purchase in a single order. This baseline is set to help leather goods manufacturers manage costs, ensure efficient production, and maintain profitability. Manufacturing leather goods involves a certain level of fixed expenses, so to offset this cost, many factories will set a minimum production requirement to keep items economically viable.

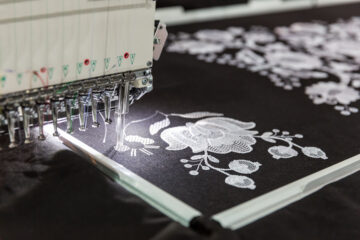

Additionally, leather goods manufacturing involves specialized machinery and skilled labor. Setting up the machinery can be time-consuming, so ensuring a more significant production run allows manufacturers to streamline the process. MOQs can vary widely depending on a factory’s type of product and manufacturing capabilities. For example, high-end leather bags may have a lower MOQ than leather wallets.

Factors Influencing MOQ

Different factories will have different MOQs. This baseline is set based on various factors, including cost and efficiency. Cost is one of the primary considerations factories use to determine the MOQ for a product. The cost of leather and other raw materials can vary significantly depending on the quality, grade, and type of materials. Setting higher MOQs allows manufacturers to purchase materials in bulk and reduce shipping costs. Additionally, producing leather goods requires certain overhead costs, including machinery and labor costs. A high MOQ spreads out these costs, making it more cost-effective for the factory.

Additionally, factories must consider the efficiency of production. Leather machinery, such as die-less cutting machines, can be time-consuming to set up and reset. A more significant production run reduces the frequency of setup changes, ultimately boosting production efficiency.

Benefits of MOQs for Buyers and Manufacturers

MOQs provide numerous benefits for factories, from cost-saving to time-saving, but these order requirements can also be advantageous to purchasers. Here are some of the critical benefits of MOQs:

- Lower Per-Unit Production Costs. Though these requirements may make a buyer purchase more than they wanted, it can lower the overall cost of each unit, making it a more financially viable endeavor. Manufacturers use MOQs to distribute fixed costs, like labor and overhead, across more units, making the cost of production more affordable per unit. This ultimately translates to cost savings for the buyer as well.

- Consistency in Quality. By reducing the amount of setup changes and repurchasing materials, manufacturers can keep a more consistent level of quality between batches. This results in less variation in the final product and a high level of quality, which is critical for distributing a quality leather product.

- Reduced Lead Times. Without additional setup changes, manufacturers can produce orders faster, delivering the desired leather products more quickly. This is particularly important in the fast-paced modern market.

By improving time-to-market and ensuring a high-quality product, MOQs help manufacturers create a win-win situation for themselves and buyers.

How Can We Help?

Softline Brand Partners, a leader in soft goods manufacturing, is here to bring your company’s designs to life. With varying MOQs between different products, we can work with companies of any size. From leather wallets to bags to home goods to other soft goods, Softline Brand Partners can help you from design to delivery. Contact us today to learn more about our domestic and overseas factories and our MOQs.