Concept to Prototype: Softline’s Design and Sampling Services

In the soft goods industry, transitioning from concept to prototype is crucial, bridging creative ideas to tangible products. This process transforms abstract concepts into physical items, which can be tested, refined, and perfected before mass production. Prototyping is essential to ensure products are both aesthetically appealing and functionally sound.

The Role of Softline in the Design to Prototype Process

Softline Brand Partners is pivotal in transforming initial concepts into tangible prototypes, particularly textiles and fine leather goods. The meticulously designed process aligns with the client’s goals and objectives to ensure the final products resonate with the target market and meet the intended functional requirements.

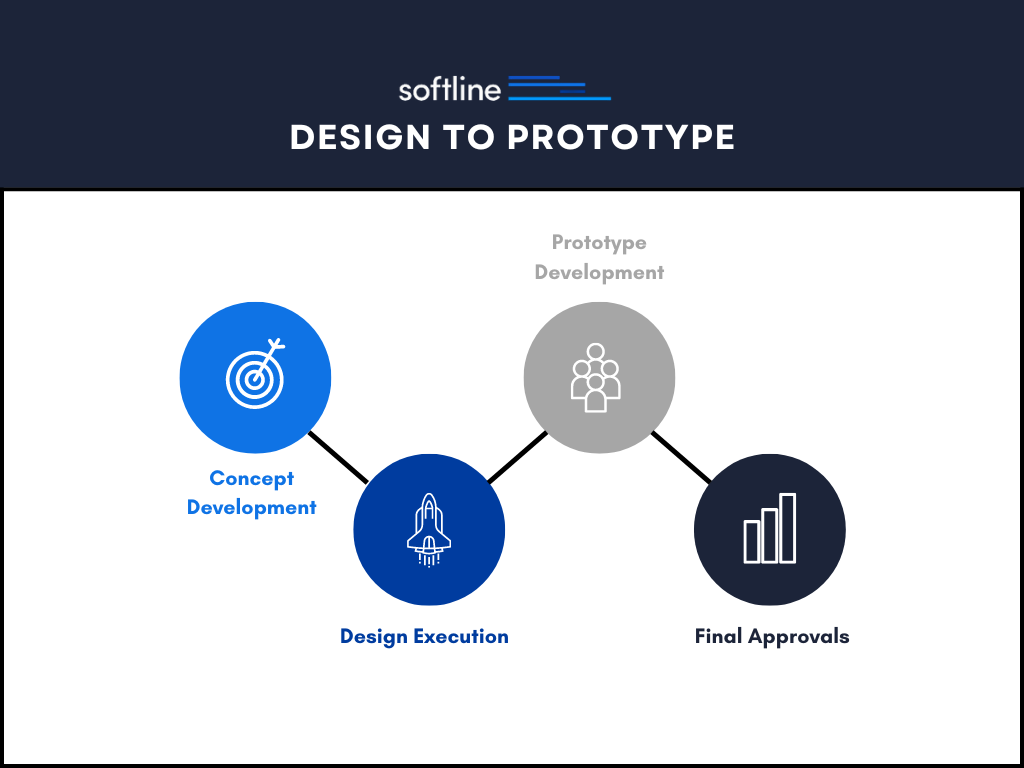

The Design to Prototype Journey at Softline

Softline’s approach to transforming concepts into prototypes is comprehensive and methodically structured. This ensures that every design meets aesthetic expectations and excels in functionality within its intended market. This journey involves several crucial phases, each contributing to the final high-quality prototype ready for production.

Concept Development and Initial Research

The process starts with an in-depth exploration during the concept development phase. Softline’s team engages closely with clients to deeply understand their vision, market needs, and end-user preferences. Detailed discussions ensure that the design concepts align with current market trends and consumer expectations. This stage sets a strong foundation for successful product realization.

Design Execution and Material Selection

Moving into design execution, Softline translates these refined concepts into tangible designs. Initial sketches are created to visualize the concept, essential for preliminary adjustments. This phase also involves material selection, where Softline’s expertise in textiles and leather is crucial. Softline recommends materials that satisfy both functional needs and aesthetic appeal. Collaboration continues to be key, with ongoing discussions about material options, lead times, and pricing to ensure alignment with the client’s budget and expectations.

Prototype Development and Refinement

Softline produces several samples with the initial design set, refining each based on detailed client feedback. This iterative prototype development process focuses on enhancing design details, adjusting materials, and improving functionality, ensuring the product meets the highest quality standards. Each prototype is evaluated rigorously, incorporating adjustments critical to aligning the final product with the client’s specifications.

Comprehensive Support and Final Approvals

Once the prototype is perfected and approved, Softline prepares a detailed tech pack and sources the required materials for production. They also order any custom tooling necessary to manufacture the final product. This end-to-end service streamlines the entire development process and guarantees that every aspect of the product is meticulously planned and executed.

Softline maintains high-level communication with clients throughout each stage, ensuring that feedback is thoroughly integrated. This collaborative approach ensures that the final product precisely reflects the client’s vision and underscores Softline’s commitment to quality and customer satisfaction. Softline’s methodical process from concept to prototype sets them apart as a leader in the soft goods manufacturing sector, making them an ideal partner for brands looking to effectively bring new products to the market.

Technology and Innovation at Softline

Softline integrates cutting-edge technology to enhance the design and prototyping stages, utilizing tools like CAD software and 3D modeling. These technologies streamline the development process and increase the accuracy of the final products.

Advanced Tools and Impact on the Development Process

CAD software allows for precise digital blueprints of products, ensuring complex designs are perfectly replicated. 3D modeling brings these designs to life before production, providing a realistic view of the final product and allowing for pre-production adjustments. This technology integration significantly accelerates the development process, enabling quick iterations and adjustments based on client feedback or new ideas while greatly enhancing the accuracy of design specifications.

These technological advancements transform how products are designed and manufactured, placing Softline at the forefront of the soft goods manufacturing industry and ensuring high-quality outcomes that meet clients’ precise needs.

Case Study Highlight: From Concept to Prototype with Softline Brand Partners

Let’s explore how these practices play out in real-world applications. One illustrative case study involves Softline’s work with Bespoke Post, a subscription box company known for its curated goods collections.

Bespoke Post: Streamlining Product Development

Bespoke Post faced the challenge of rapidly developing new products to meet the monthly release demands of their subscription boxes. Partnering with Softline, they needed to efficiently transform diverse product concepts into ready-to-market goods.

Conceptualization and Collaboration

Softline worked closely with Bespoke Post to pinpoint each product’s requirements and expectations, ensuring a clear understanding of the target market and product use. This phase was critical in aligning the design team’s efforts with Bespoke Post’s brand identity and customer preferences.

Rapid Prototyping

Softline swiftly moved from sketches to physical samples, leveraging their in-house design and prototyping capabilities. This rapid prototyping allowed Bespoke Post to visualize the end products sooner, enabling quicker feedback and necessary iterations to perfect each item before final approval.

Outcome and Impact

The collaboration resulted in the on-time delivery of high-quality, unique products that resonated well with Bespoke Post’s subscribers.

This case exemplifies how Softline’s efficient prototyping services can significantly reduce time-to-market and enhance product quality, helping clients stay competitive and responsive to market trends. It also highlights the practical application of a collaborative approach to product development.

Bringing Ideas to Life with Softline

A meticulous design-to-prototype process ensures that a product aligns with market trends and consumer expectations and establishes a foundation for its success in the competitive market. This process involves thorough research, collaborative design development, detailed prototyping, and continuous feedback integration, all essential to refining the product to meet the highest standards of functionality and aesthetics.

Choosing Softline Brand Partners as a collaborator in this journey offers numerous advantages. Softline’s commitment to quality and client satisfaction is evident in every step of its process. With its advanced tools and technologies, Softline enhances the design and prototyping phases, ensuring precision and efficiency. Moreover, its emphasis on client collaboration fosters a dynamic where feedback is deeply integrated, resulting in products that meet and often exceed client expectations.

For any brand looking to navigate the complexities of product development in the soft goods sector, partnering with Softline means engaging with a team dedicated to delivering excellence. Softline’s proven track record, illustrated through various successful projects, demonstrates its capability to transform creative visions into market-ready products, making it an ideal partner for achieving outstanding results.

Softline for Start-Ups Resource Guide

Building a Brand in the Soft Goods Market

Intellectual Property Protection in Fashion and Soft Goods

Concept to Prototype: Softline’s Design and Sampling Services